Trace Heating

Trace heating is essential for maintaining pipe, roof and ramp temperatures, particularly in business-critical industrial and manufacturing environments. In addition, it helps reduce running costs and minimise the risk of damage in cold conditions. With a proven track record, we are an ideal supply partner for trace heating system installation and maintenance across East Anglia.

As part of the Diamond Controls Group, our experienced engineers provide a complete design, installation and maintenance service. We are an authorised Chemelex RAYCHEM installer, with CompEx-qualified design specialists and ISO 9001 and ISO 14001 accredited processes.

Whether upgrading an existing system or installing a new heat tracing solution, we deliver reliable, bespoke specifications to suit your requirements. Trace heating systems help reduce running costs and minimise the risk of damage in cold conditions.

Our Services:

Looking to buy Trace Heating Supplies online?

We now offer a supply and distribution service via our website traceheatingsupplies.com

Trace Heating Applications:

Products – Trace Heating Systems

Please find below examples of our more commonly installed Trace Heating Systems. Please contact us for further information.

A Solution For Every Sector

If it’s your first time exploring trace heating, please see some common requirements below:

Process Temperature Maintenance

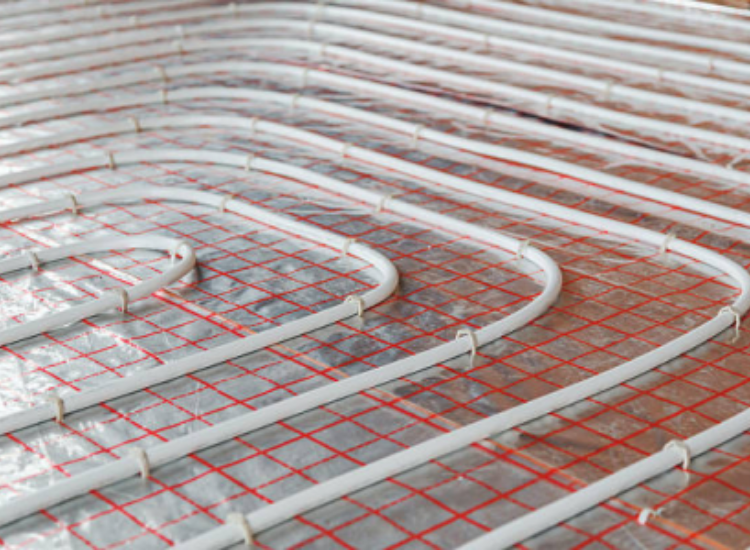

Many manufacturing processes require the transport of liquid products from one area of a facility to another. Failure to accurately control their temperature could cause spoilage or solidification. It can also negatively affect the running of production equipment and increase maintenance requirements. Trace Heating Systems can be installed to a pipeline or a vessel, using the appropriate cable heating technology, control system and quality components.

HWAT (Hot Water Temperature Maintenance)

Hot Water System (HWS) trace heating is becoming increasingly common in commercial properties, offering significant economic benefits while eliminating the need for traditional recirculating systems. It maintains hot water at the correct temperature throughout the distribution pipework and operates with high efficiency, reducing both water consumption and energy use for optimal performance. Hot Water Temperature Maintenance (HWAT) systems require minimal upkeep and are highly cost-effective to install.

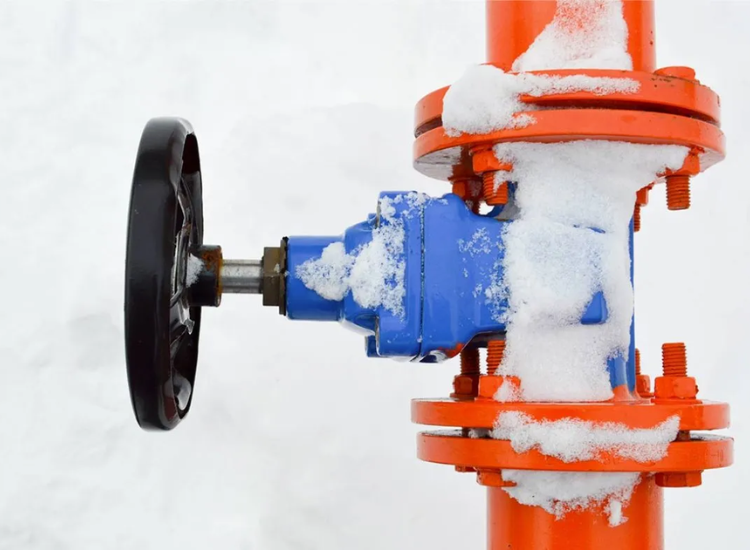

Frost Protection

As the most common application for Trace Heating, frost damage, including frozen pipework and broken fittings, is a concern during the cold winter months. Water damage and costly disruption to operations and processes can be avoided by installation of this low-maintenance and highly effective system. Trace heating cables maintain fluid temperatures by replacing the lost energy through pipe insulation. We consider all of the factors, including the location and requirements of the system, before delivering your purpose-built requirement.

Critical Areas

Access areas such as ramps, driveways and walkways can become dangerous during harsh weather events, making them unusable and unsafe. Electric snow melting systems can prevent snow and ice build-up and leave you with a safe route for vehicles, machinery and people. These systems are extremely effective, low maintenance and can help keep your facilities fully operational during the winter months.

View more client feedback